Novitech is fully committed to ongoing research and development of our ILI tool fleet. Continuous research is also performed on detection, and sizing algorithms for features and flaws. During the development of our ILI tool technology, Novitech has been continuously focused in advancing the design of our Micron AMFL, CMFL, IDD and other sensors systems.

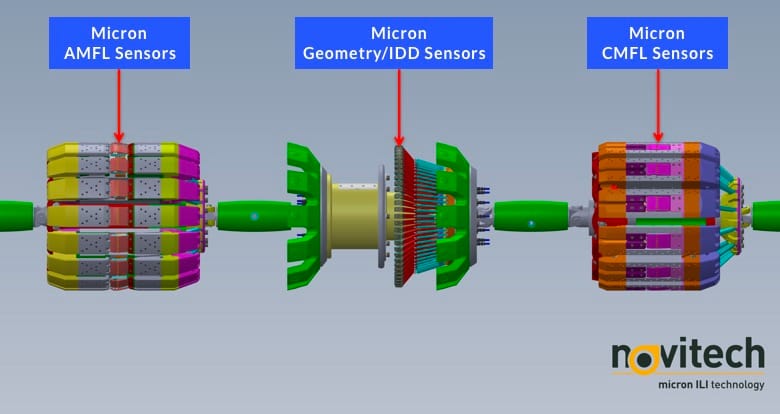

Micron ILI Technology Sensor Systems

Allows the use of multiple main sensor systems for confirming and prioritizing critical flaws.

AMFL & CMFL Sensors

Both our AMFL and CMFL sensors have the highest sensor density, sensitivity, and sampling rates allowing detection and sizing of very small pin holes and cracks in both the axial and circumferential directions. This can be done with one tool run or by comparing separate tool runs as required by our customers.

IDD-SMSM

Our Micron IDD-SMSM (Internal Depth Detection – Stress MeasurementSM) sensor systems can detect pipeline features, internal metal loss, significant external metal loss, and the high stress areas around severe corrosion and cracking. This allows the use of multiple main sensor systems for confirming and prioritizing critical flaws.

Crack Detection and Sizing

These threats include different forms of cracking from long seam anomalies, cracking associated from some forms of mechanical damage, to stress corrosion cracking. Cracks in both the axial and circumferential directions can be investigated using both Axial and Circumferential MFL field directions.

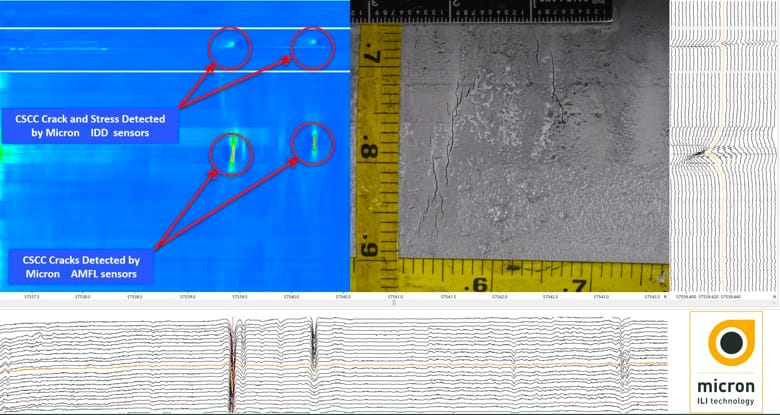

Field and Lab Examples

Pull Testing Over both Natural and Artificial Flaws

Novitech has a comprehensive inventory of piping with both artificial and natural flaws from 6” to 16” in diameter. These flaws are used for both commissioning and calibration of our Micron ILI tools. We are performing on going research in SCC crack detection and advanced detection and sizing of pin hole corrosion. Shown below is an example detection of flaws from pull testing.

Mechanical Compliance and Force Measurements

Using our state-of-the-art facilities in Toronto and our operating base in Denver we can perform mechanical compliance testing and flaw detection and sizing for all major integrity threats.

Water testing for differential pressures and bend compliance are carried out during research and development, testing and commissioning for each tool version and pipe diameter.

Testing can be performed indoors and at any time during the year from one or both of our locations in Canada and the United States. Compliance testing up to pressures of 250 psi and flow rates of up to 500 gallons per minute can be carried out using our array of high-pressure pumps and tanks as shown below.

Our setup time to perform testing with our existing piping, or our customers piping is fast and efficient. Many tests can be performed in just a few days from start to finish.