Every once in a while, a new technology, an old problem, and a big idea turn into an innovation

Novitech would like to thank everyone who participated in voting this year for the PPIM2024 innovation award. We’re happy to say that this year we’ve won!

We were founded on the purpose of providing experience driven expertise that’s always been demanded by the Oil and Gas industry. With that being said, to be able to position ourselves to

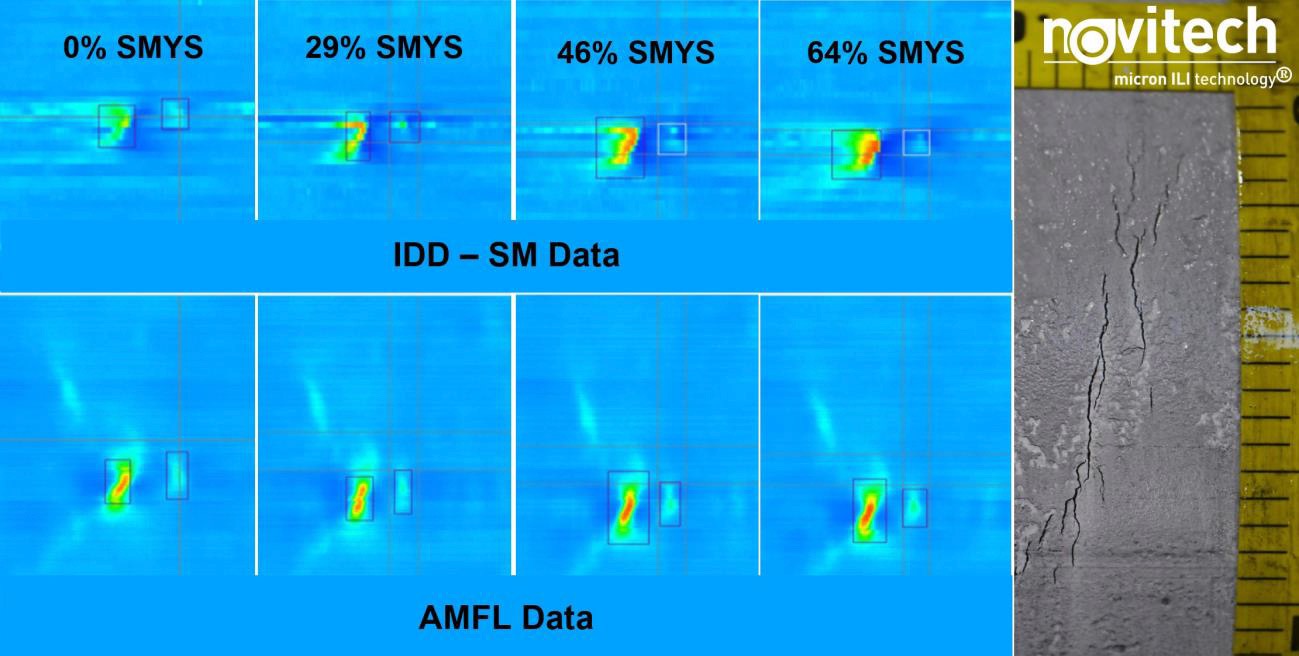

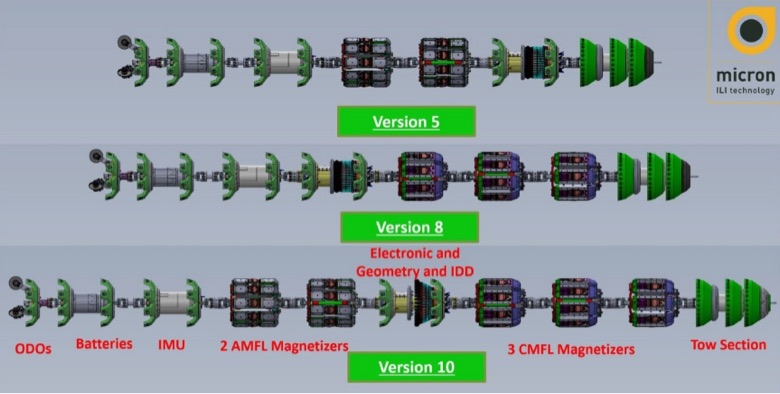

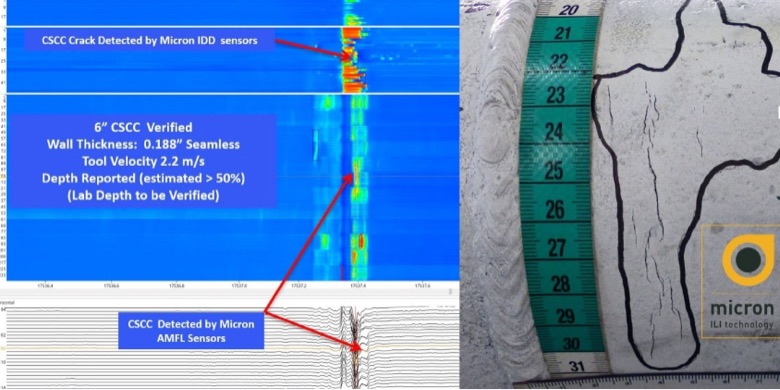

offer pipeline operators a more unique integrity program, we’re constantly thinking outside the box – Our innovation this year, for the Integrity Management of Off-Axis SCC by Direct Detection through an ILI system & Engineering Assessment, proves that we are doing just that and taking Inline Inspection to a whole new level.

Thank you, to our clients for stopping by our booth at the show this week and for those who were able to make it out to our reception on Tuesday evening as well – What a week! PPIM creates such a huge buzz, and it is the perfect place for Industry personnel to come together and connect. We’re thrilled to have gotten the chance to see and speak with you all there and we’re looking forward to future opportunities to do the same!

Our mission for 2024 is to continue reaching new heights with our Micron ILI Technology® and Data Analysis. While we further advance the standards of pipeline inspection in our efforts of making pipeline operations safer, more efficient and environmentally friendly, we hope that you’ll join us along the way… (There’s lot’s in store!)

For more information about Novitech, reach out to us at, info@novitechinc.com a member of our team would be happy to hear from you!